- Home

- About us

- Products

Browse By

Product

- A0000 | Stainless Steel Slatband Chains

- B0000 | Plastic Slatband Chains

- C0000 | Chain Sprockets

- D0000 | Chain Idler Wheels

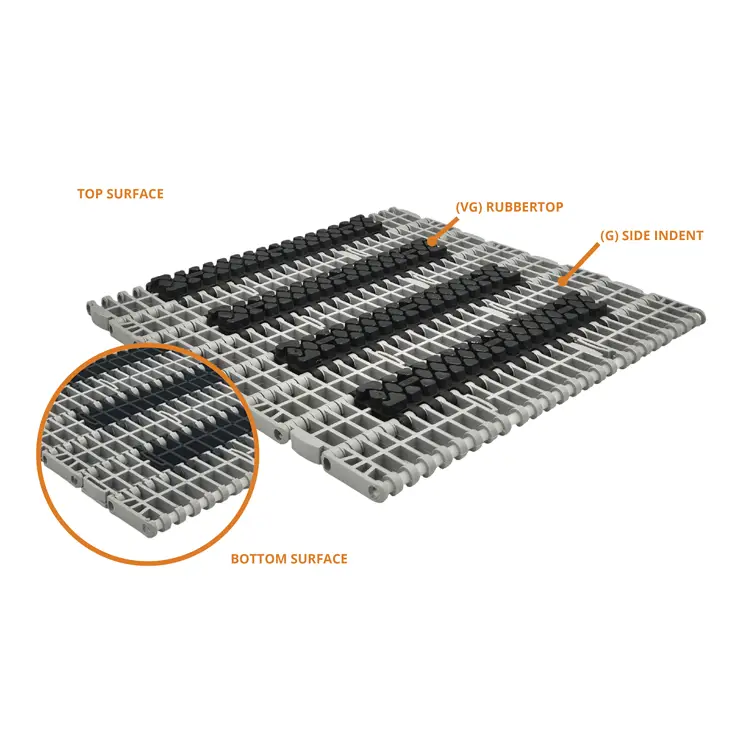

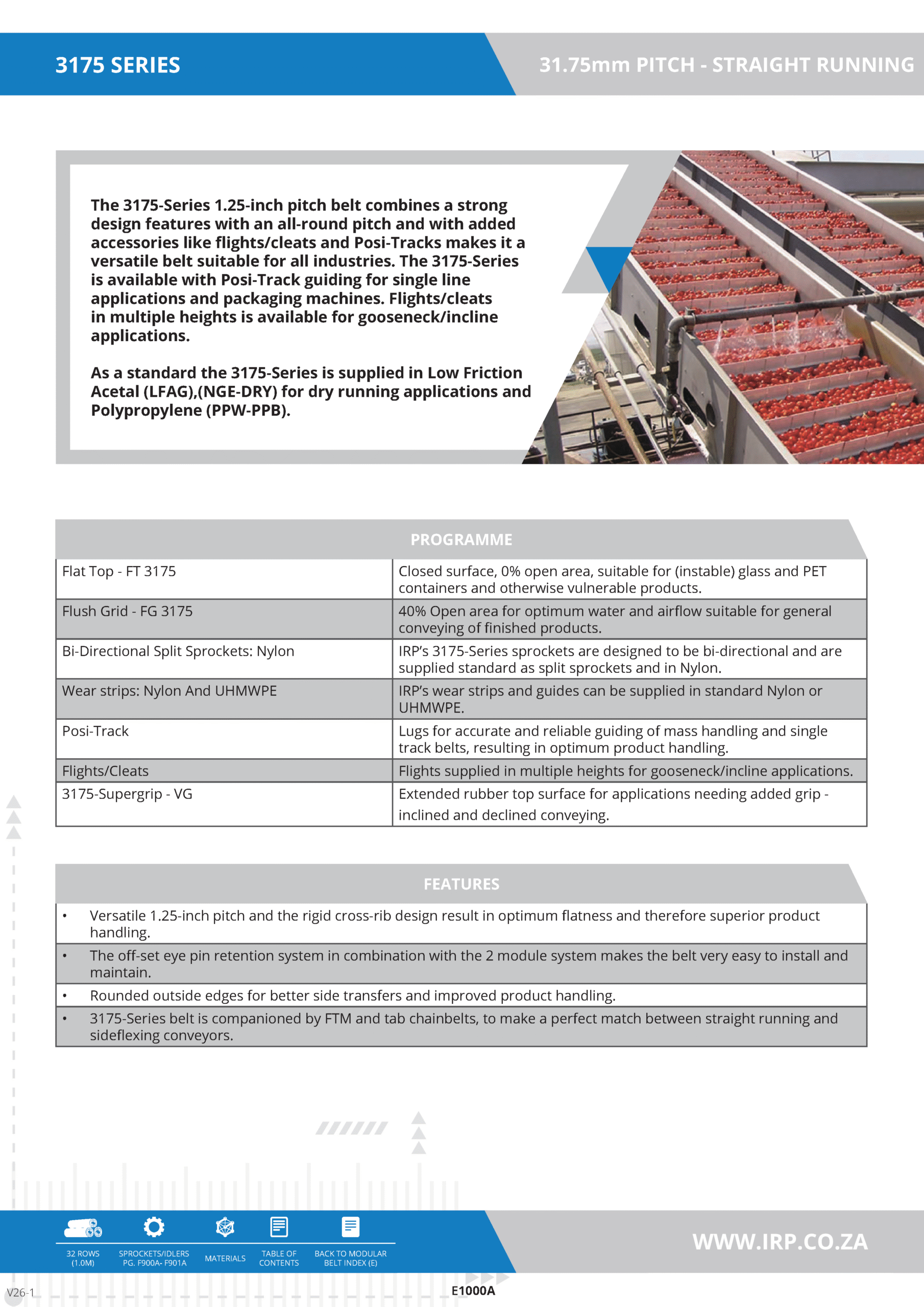

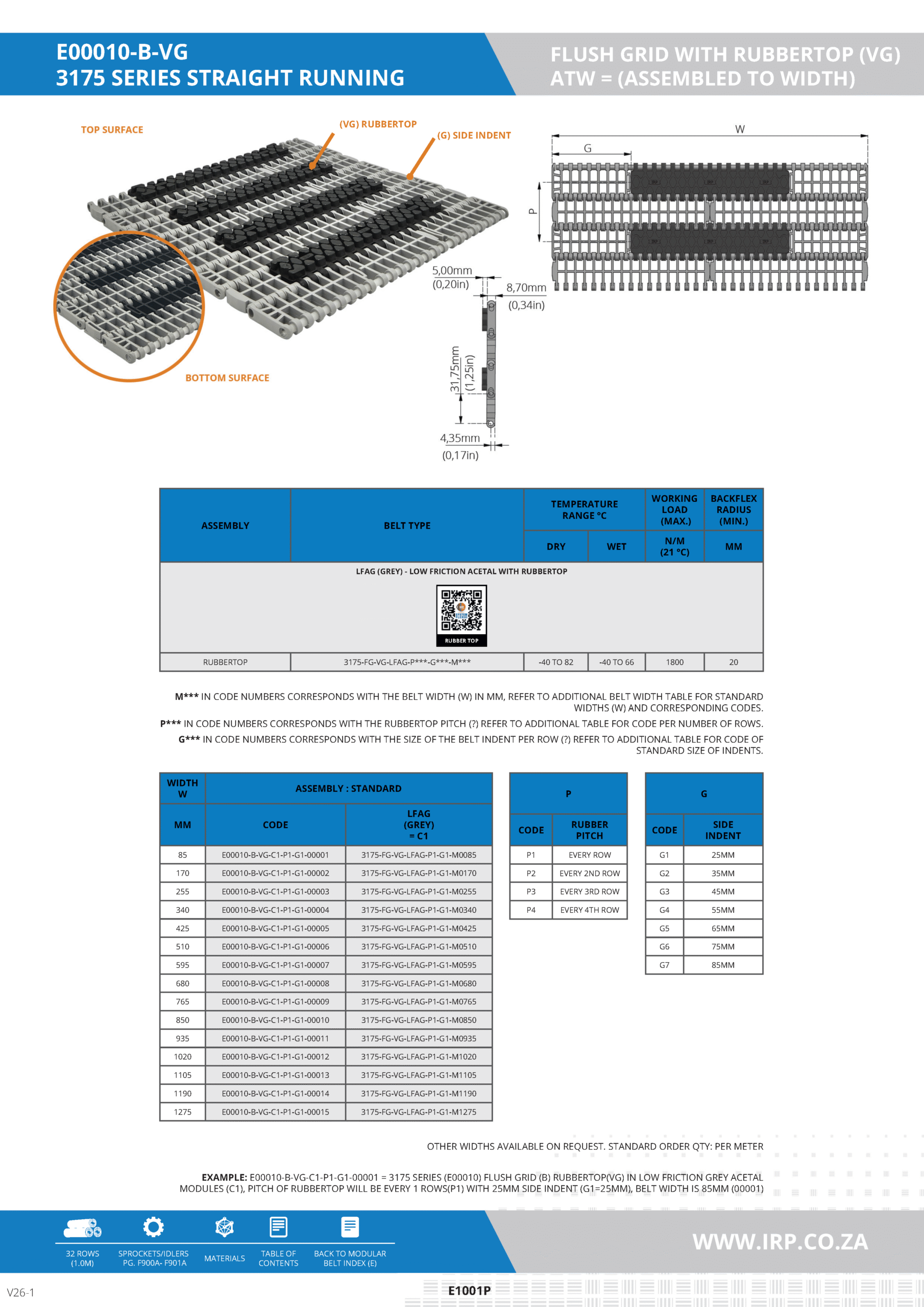

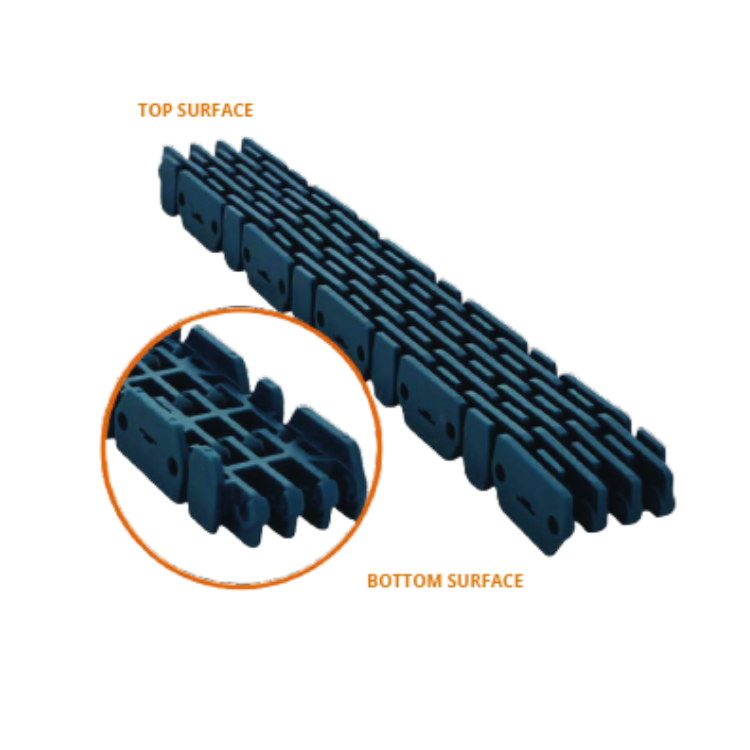

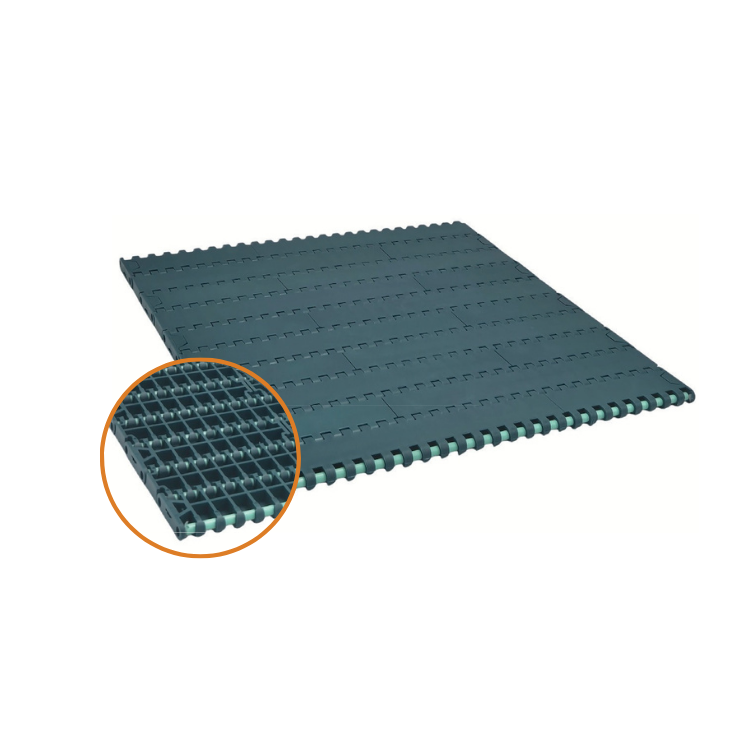

- E0000 | Modular Belts

- F0000 | Modular Belt Sprockets

- G0000 | Corner Tracks/ Curves/ Bends/ Straight Sections

- H0000 | Chain And Belt Return Systems

- J0000 | Side Guide Solutions

- K0000 | Side Guide Bracket Solutions

- L0000 | Frame & Support Structures

- W0000 | Wear Strips & Chain Guide Solutions

- Solutions

Browse By

Solution

- Chemical-Resistant Applications

- Cold/Freezing Temperatures Applications

- Dry Running Applications

- Dynamic Transfer System Applications

- Extra Low Friction Applications

- High Performance Polymer Applications

- Low Back Pressure Applications

- Metal-free Polymer Applications

- RubberTop Applications

- Ultra-High Temperature Polymer Applications

- Modular Belt Applications

- Plastic and stainless steel slatband chain Applications

- Chain Sprockets and Idler Wheel Applications

- Conveyor Support Component Applications

- Conveyor Audits

- Reverse Engineering

- Conveyor Insights

- Contact us